LGP

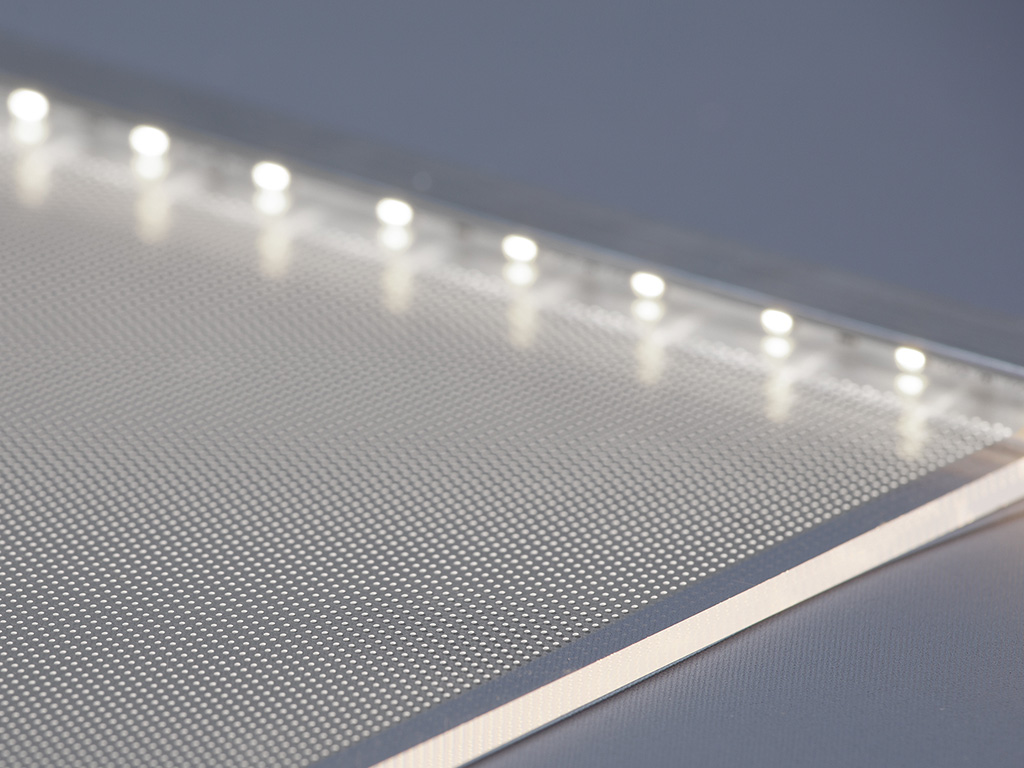

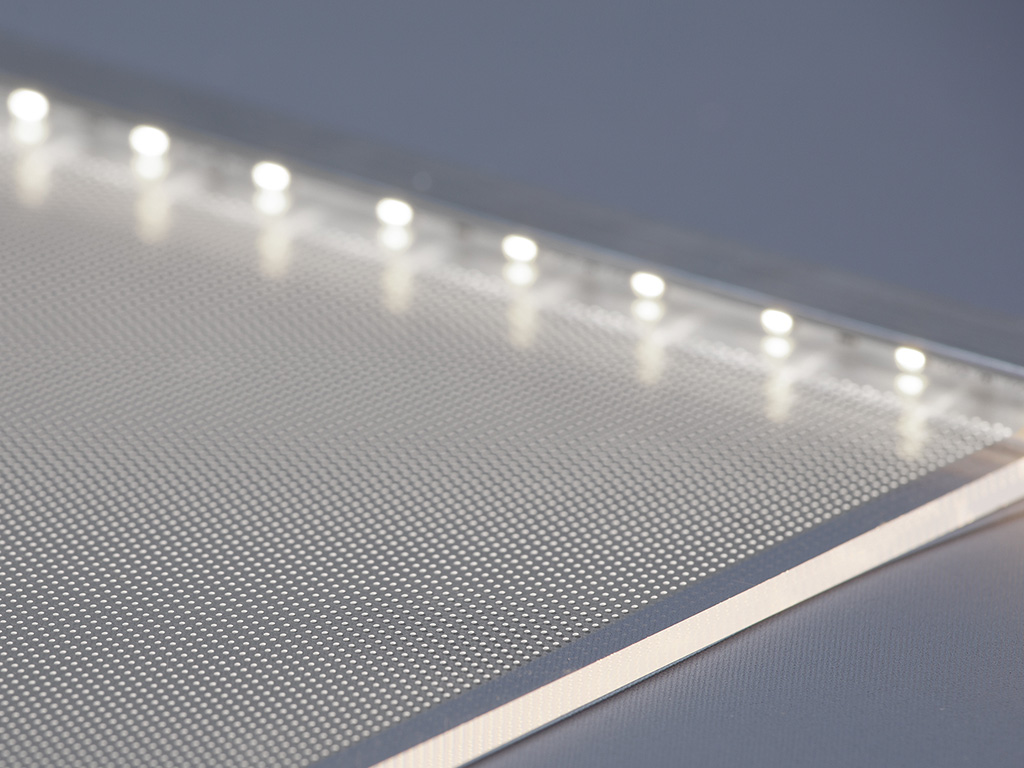

Optimized dot matrix and acrylic cut to perfection ensures 100% uniform light distribution and maximum intensity

LGP

Optimized dot matrix and acrylic cut to perfection ensures 100% uniform light distribution and maximum intensity

A modern lighting solution

Light Guide Panels (LGP)

Tested technology

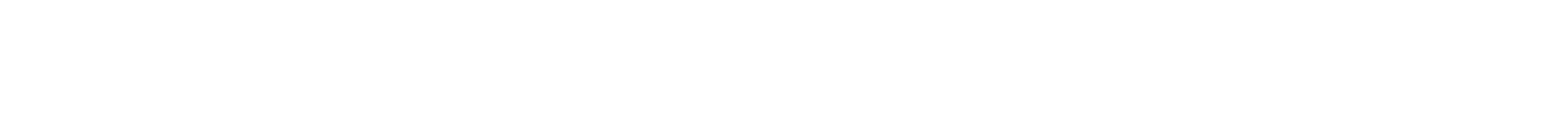

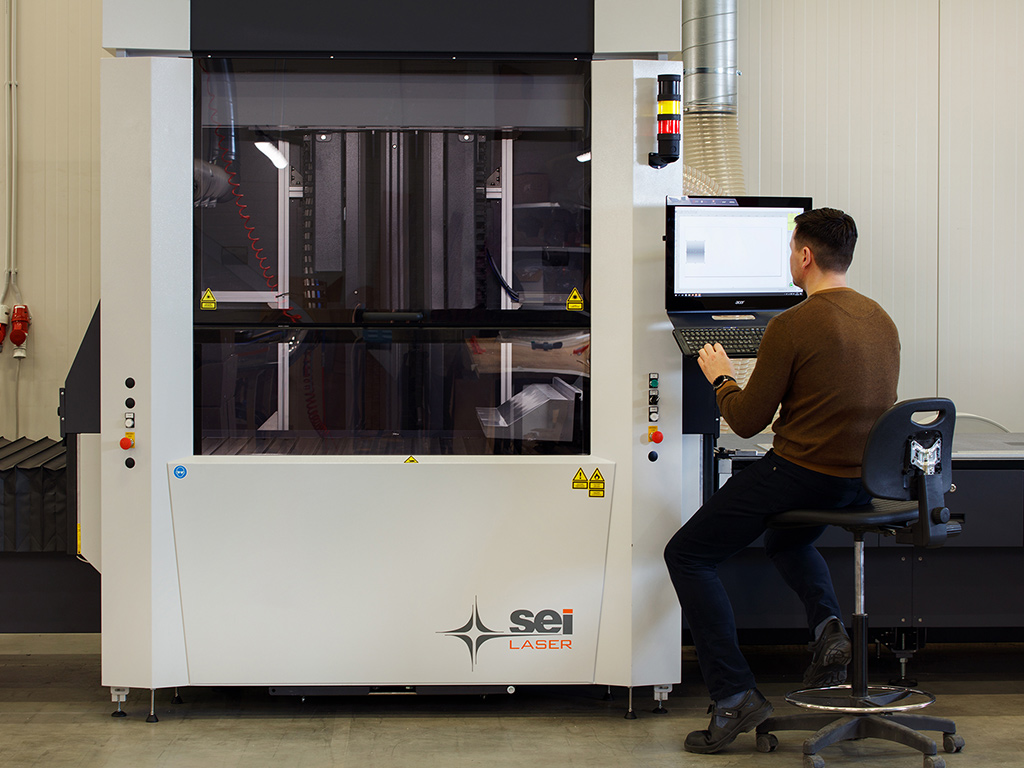

First of all, a unique optimized dot pattern is designed using special software, which is then transferred to an acrylic panel using laser engraving. The density of the dot pattern is sparser near the LED source, but moving further way, the density of the pattern becomes greater. This ensures uniformity of light throughout the panel.

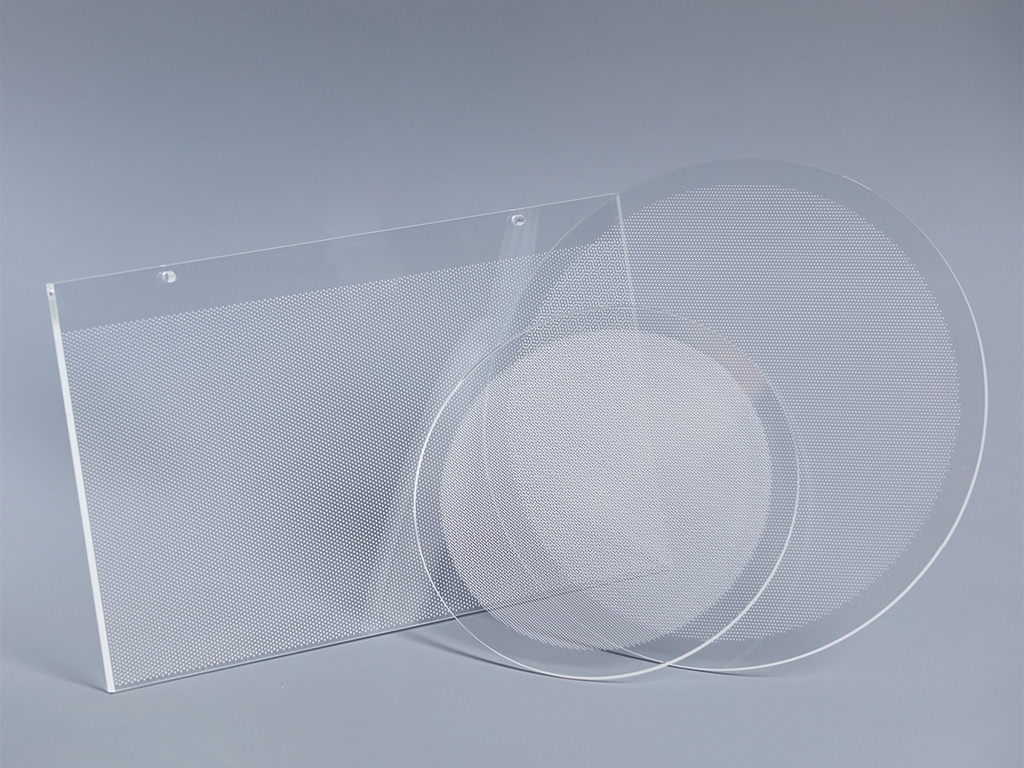

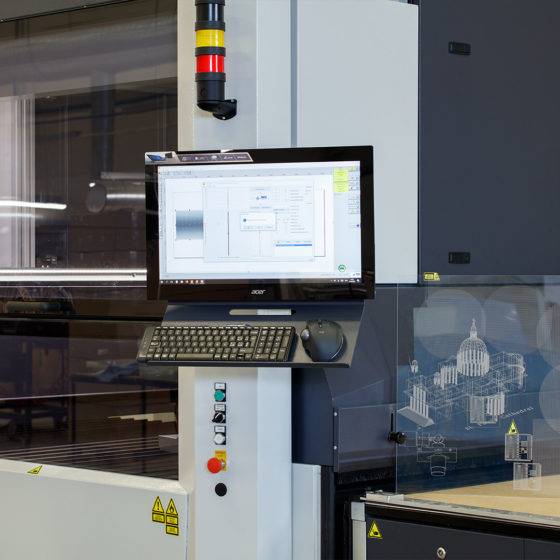

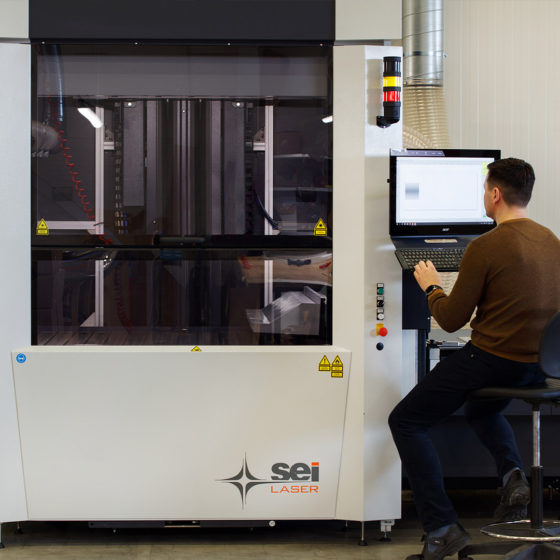

Always precise

Our special equipment and innovative technologies allow full control of the pattern, distribution, size and depth of the dots engraved on the panel.

The maximum size of a panel is 1200×3050 mm.

- perfect light transmittance

- uniform light distribution

- shape and size up to the customer

A modern lighting solution

Light Guide Panels (LGP)

Tested technology

First of all, a unique optimized dot pattern is designed using special software, which is then transferred to an acrylic panel using laser engraving. The density of the dot pattern is sparser near the LED source, but moving further way, the density of the pattern becomes greater. This ensures uniformity of light throughout the panel.

Always precise

Our special equipment and innovative technologies allow full control of the pattern, distribution, size and depth of the dots engraved on the panel.

The maximum size of a panel is 1200×3050 mm.

- perfect light transmittance

- uniform light distribution

- shape and size up to the customer